laminate wooden floor manufacturer

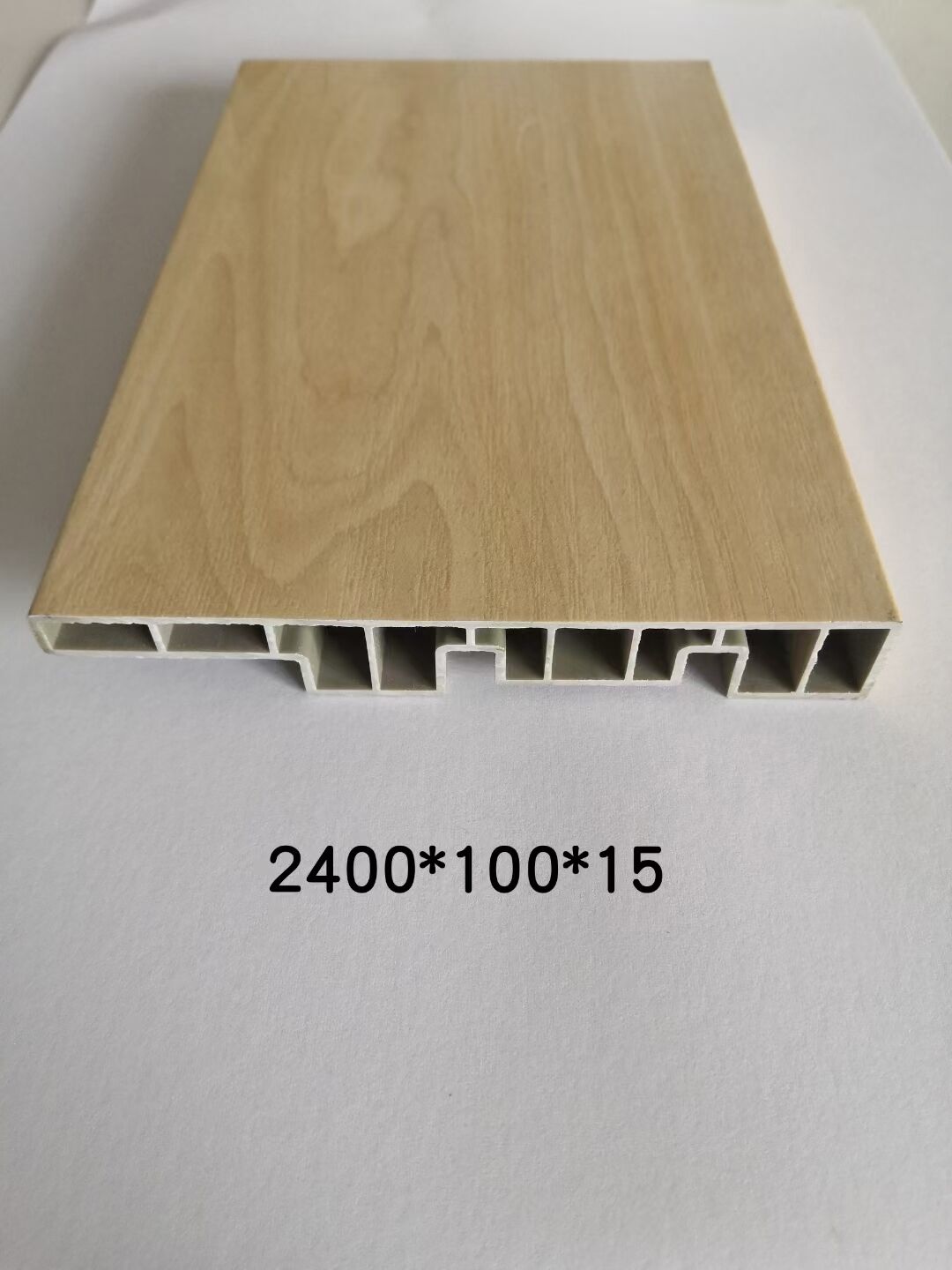

A laminate wooden floor manufacturer represents a cornerstone in modern flooring solutions, combining advanced manufacturing technology with aesthetic appeal. These facilities employ state-of-the-art production lines that create durable, multi-layered flooring products designed to mimic natural wood while offering superior resistance to wear, moisture, and daily stress. The manufacturing process involves four essential layers: a wear-resistant overlay, a decorative layer featuring wood grain patterns, a high-density fiberboard core, and a stabilizing back layer. Modern manufacturers utilize precision engineering and computer-controlled systems to ensure consistent quality and precise dimensional accuracy. They implement advanced pressing techniques that fuse these layers under high pressure and temperature, creating a robust and stable product. The facilities are equipped with sophisticated quality control systems that monitor every production stage, from raw material selection to final product inspection. Additionally, these manufacturers often incorporate sustainable practices, using recycled materials and implementing energy-efficient production methods. Their operations typically include research and development departments focused on innovating new textures, patterns, and installation systems to meet evolving market demands and environmental standards.