luxury vinyl flooring manufacturer

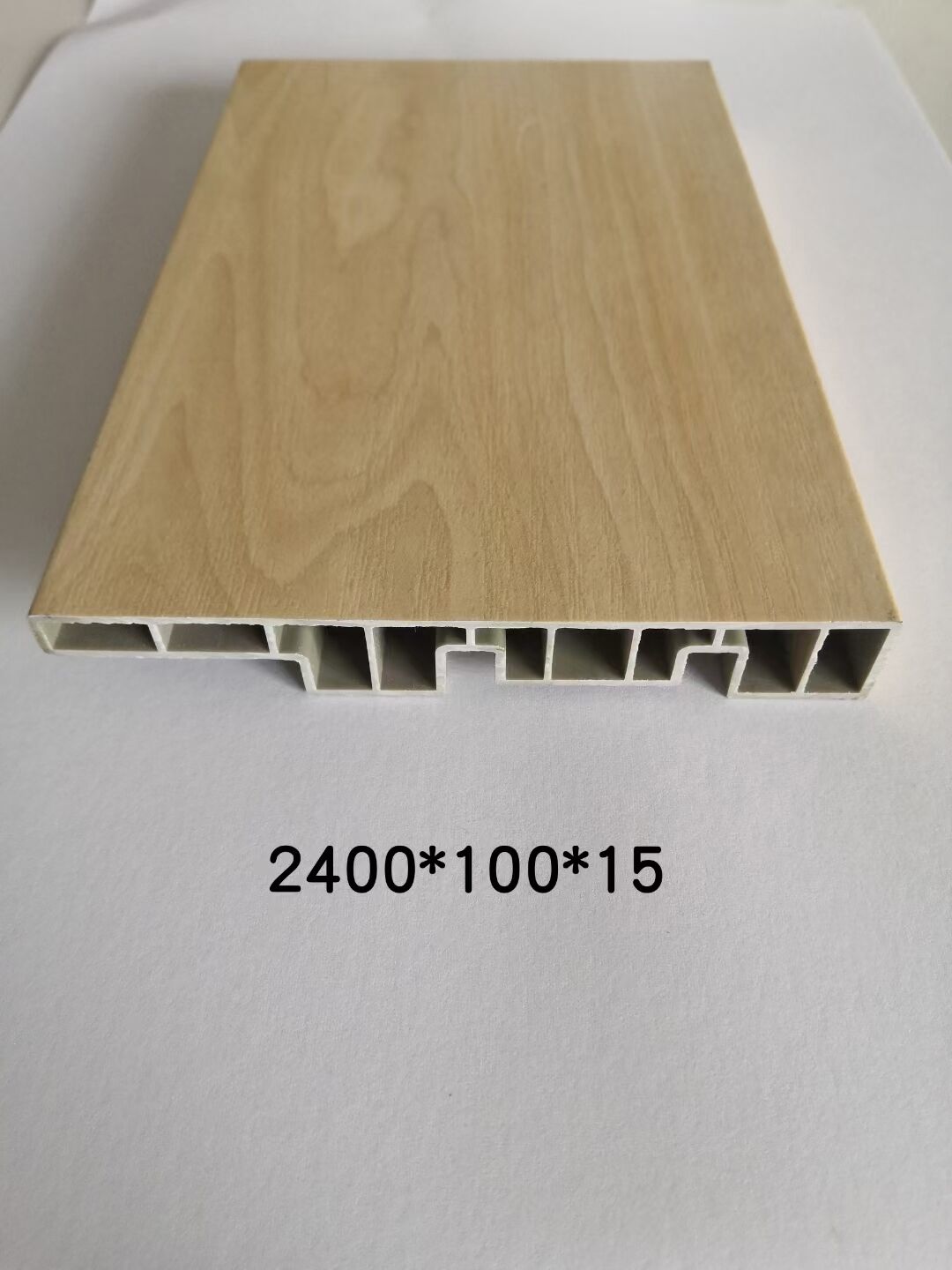

A luxury vinyl flooring manufacturer represents the pinnacle of modern flooring innovation, combining cutting-edge technology with aesthetic excellence. These industry leaders utilize advanced manufacturing processes to create premium vinyl flooring solutions that perfectly replicate the look of natural materials while offering superior durability and maintenance benefits. The manufacturing facility employs state-of-the-art equipment and precision engineering to produce multilayer vinyl planks and tiles that feature high-definition printing technology, allowing for incredibly realistic wood and stone appearances. Their production lines incorporate UV-curing systems, ensuring optimal wear layer protection, while specialized pressing techniques create authentic surface textures. The facility's quality control measures include rigorous testing for wear resistance, water resistance, and dimensional stability. Environmental consciousness is integrated into the manufacturing process, with many facilities implementing sustainable practices and using recyclable materials. The manufacturer's capabilities extend to producing various vinyl flooring formats, from traditional planks to innovative rigid core products, all designed to meet diverse commercial and residential applications. Advanced acoustic underlayment options and specialized coating technologies are also incorporated to enhance the final product's performance characteristics.