luxury vinyl plank manufacturer

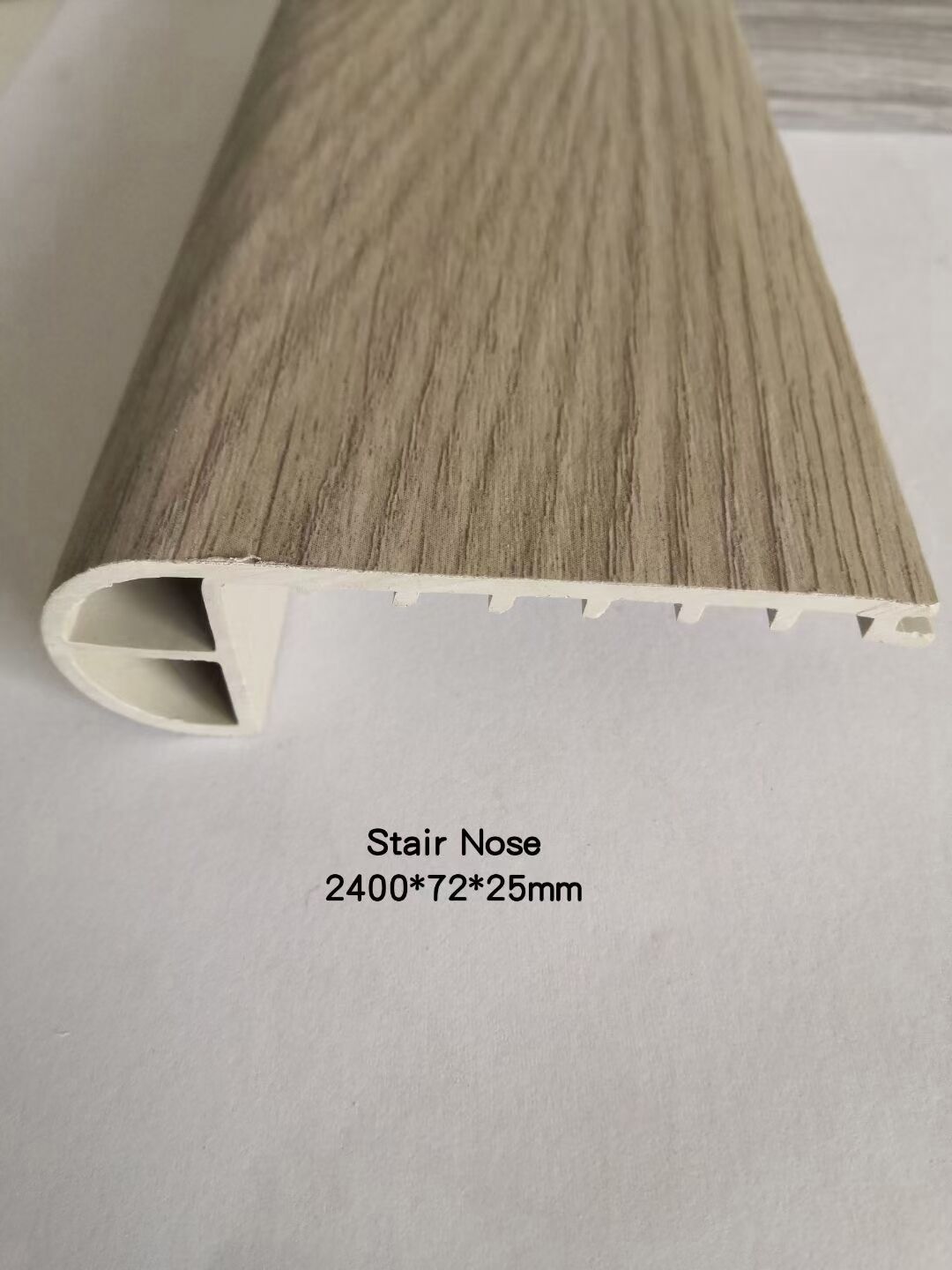

A luxury vinyl plank manufacturer represents a cutting-edge facility dedicated to producing high-quality vinyl flooring solutions that combine aesthetics with durability. These state-of-the-art manufacturing facilities utilize advanced technology to create planks that accurately replicate the look and texture of natural materials while offering superior performance characteristics. The manufacturing process involves multiple layers, including a wear layer, design layer, core layer, and backing layer, each contributing to the product's overall quality and longevity. Modern manufacturers employ digital printing technology to achieve incredibly realistic wood and stone appearances, while innovative surface treatments create authentic textures. The facilities are equipped with precision cutting tools and quality control systems that ensure dimensional accuracy and consistent product quality. Environmental considerations are integrated into the manufacturing process, with many facilities implementing sustainable practices and using recycled materials where possible. The production lines are capable of creating various plank sizes and styles, accommodating different installation methods including click-lock systems and glue-down applications. These manufacturers also maintain rigorous testing protocols to ensure their products meet or exceed industry standards for wear resistance, water resistance, and safety requirements.