plastic flooring factory

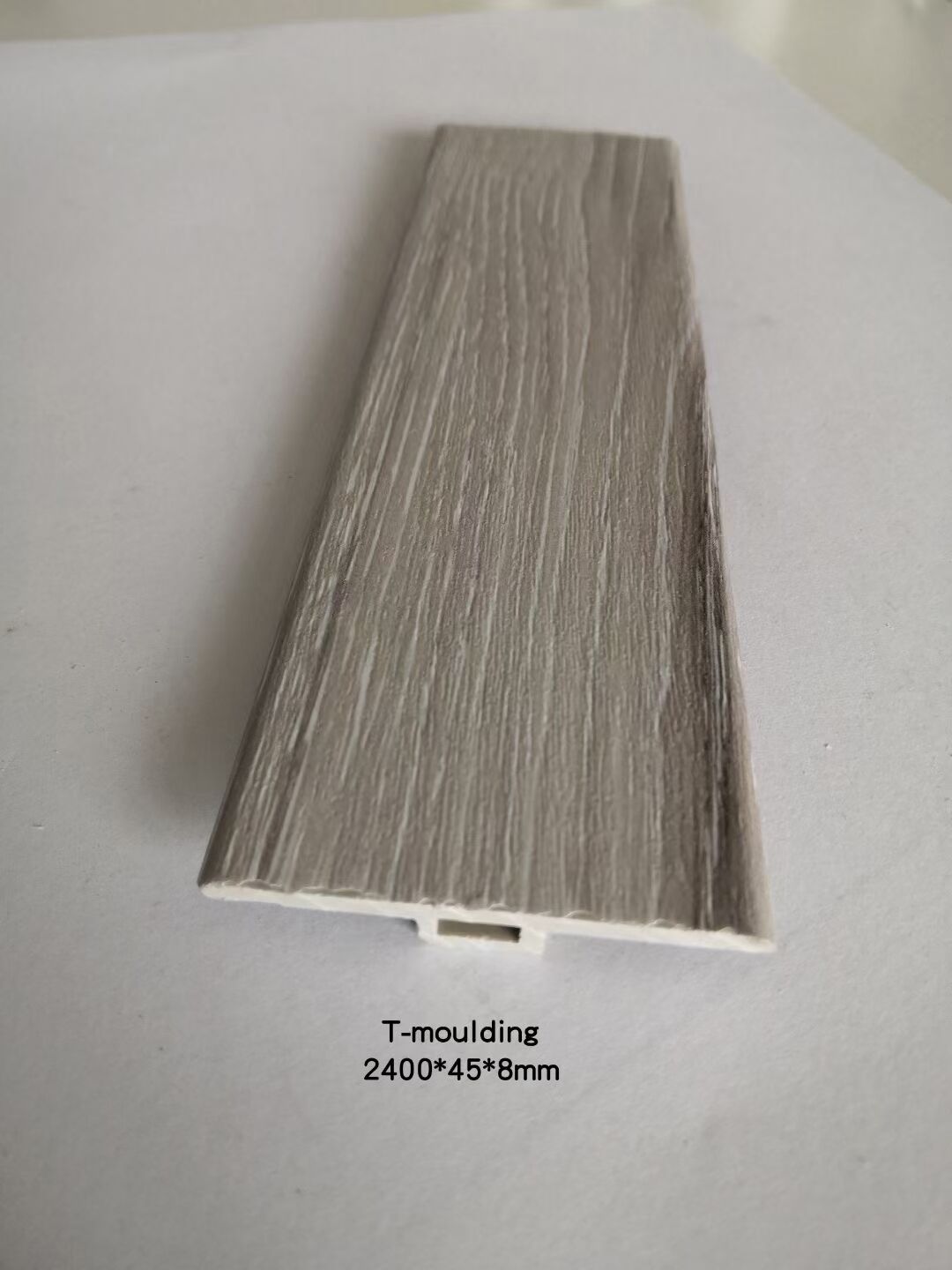

A plastic flooring factory represents a state-of-the-art manufacturing facility dedicated to producing high-quality flooring solutions using advanced polymer technologies. These facilities incorporate cutting-edge automation systems and precision machinery to transform raw plastic materials into durable, attractive flooring products. The production line typically features multiple stages, including material mixing, extrusion, molding, and finishing processes, all carefully controlled to ensure consistent quality. Modern plastic flooring factories utilize computer-aided design and manufacturing systems to create diverse patterns and textures, meeting various aesthetic and functional requirements. The facility's quality control laboratory continuously monitors production parameters and conducts rigorous testing to ensure products meet international standards for safety, durability, and environmental compliance. Advanced recycling systems are often integrated into the manufacturing process, promoting sustainability by minimizing waste and incorporating recycled materials when possible. The factory's warehouse management system ensures efficient storage and distribution of finished products, while the research and development department works on innovative solutions to meet evolving market demands.