SPC Flooring Market Growth Trajectory and Key Drivers

Global SPC Flooring Market Valuation Projections

Global SPC flooring sales are expected to hit around $12 billion by 2030, mainly because people keep renovating homes and businesses continue developing new commercial spaces. The North American and European markets show especially high interest in these floors since consumers there care deeply about eco friendliness and how their spaces look visually. We're seeing this reflected in numbers too the industry should grow at roughly 6.8% each year as different sectors need tough yet affordable flooring options. These figures tell us something important about where the market is headed. As architects and designers change what they want from interior spaces, SPC flooring keeps gaining ground across various applications.

Residential vs. Commercial Adoption Patterns

SPC Flooring is becoming popular at different rates depending on whether it's used in homes or businesses. Homeowners tend to go for SPC because it saves money, looks good, and installs quickly compared to older options. Businesses see things differently though. They care more about how tough the flooring is and how flexible it can be in design. We're seeing especially fast growth in places like hotels and stores where lots of people walk around all day. The numbers back this up too many commercial projects now choose SPC over other materials according to recent research. All these trends point to why more and more people across various industries are turning to SPC flooring solutions that work well both visually and functionally.

Asia-Pacific Dominance in Production and Consumption

When looking at both production numbers and how much gets consumed, the Asia-Pacific region clearly dominates the SPC Flooring market landscape. China plays a major role here, benefiting from vast raw material supplies and pricing models that give manufacturers a real edge over competitors elsewhere. What drives demand across the region? A combination of factors including cities growing at breakneck speed, construction projects popping up everywhere, and consumers increasingly opting for eco-friendly options when they can afford them. Government policies also play their part, with several countries rolling out incentives for companies adopting greener manufacturing methods. While there's no doubt about Asia-Pacific's current leadership position, whether this will continue depends on how well local producers can maintain quality standards while keeping costs down compared to emerging markets elsewhere.

Technological Innovations Reshaping SPC Flooring Trends

Digital Emboss-in-Register Printing for Hyper-Realistic Textures

The digital emboss-in-register printing technique is changing things big time for SPC flooring manufacturers, as it creates textures so realistic they almost feel like the real deal. What makes this tech stand out is how it lines up the actual texture with whatever pattern gets printed on top, giving floors both amazing looks and that authentic hand feel consumers love. These kinds of improvements definitely matter to shoppers who want their homes to look expensive without breaking the bank. Companies now can offer floors that look just like wood or stone but cost way less than genuine materials. Looking at recent sales numbers tells us something interesting too many stores report better performance from these digitally embossed options compared to traditional ones. So while not everyone knows all the technical details behind embossing, most people recognize when flooring feels special, which explains why this technology keeps gaining ground in showrooms across the country.

Thinner, High-Strength Core Designs Reducing Carbon Footprint

New developments in core material tech have made it possible to produce SPC flooring that's both thinner and tougher than before. The changes mean companies use fewer raw materials overall while shipping takes less energy too, which is good news for the environment. Some studies suggest lighter floorboards cut down on carbon emissions during transport by around 25%. With green concerns growing all the time, factory owners are really pushing eco-conscious designs these days. Products with those green certifications now stand out on store shelves as major selling features in the competitive SPC flooring sector.

Integrated Radiant-Heat Film Systems

Adding radiant heat film systems to SPC flooring represents something pretty big for comfort and saving on energy bills. The tech works really well for people who want their homes to be smarter these days because it heats things up better than traditional methods while spreading warmth evenly throughout rooms. Homeowners typically see around 30% less on their monthly heating costs after installation. We're starting to see this tech show up everywhere from apartments to office buildings now. Eco friendly folks love it since it lets them enjoy luxurious underfoot warmth without feeling guilty about wasting resources. Basically, what we're looking at here is a complete shift in how people think about making their living spaces comfortable and stylish all at once.

Sustainability as a Market Differentiator

Bio-Based PVC and Recycled Limestone Formulations

Manufacturers are turning to bio-based PVC and recycled limestone in SPC flooring because people want greener options these days. These new formulas cut down on our dependence on old fashioned fossil fuels while making it easier to recycle flooring at the end of its life cycle. The truth is, bio materials work just as well as conventional ones but leave a smaller carbon footprint. Market research tells us something interesting too about consumer preferences. More than seven out of ten shoppers actually look for products made with sustainable ingredients first. That kind of demand makes sense why companies keep investing in these eco friendly alternatives despite what some might think about their effectiveness compared to standard materials.

ESG-Compliant Manufacturing Processes

The ESG framework is now making waves across the flooring sector, pushing companies to rethink how they operate responsibly. Manufacturers who integrate these ESG principles into their production methods tend to see stronger customer connections and actually gain ground in the marketplace where green credentials matter increasingly. When companies put ESG at the forefront, they don't just follow trends but become genuine trailblazers within their field. Recent surveys indicate around 56 percent of shoppers prefer buying products from companies dedicated to sustainability efforts. This isn't just a passing fad anymore; it reflects real shifts in what consumers value when making purchasing choices today.

Waterproof Performance Enhancing Durability

SPC flooring stands out because it won't get damaged when exposed to water, making it last longer and work better in wet spots around the house like kitchens and bathrooms. When companies combine this water resistance feature with green manufacturing methods, they hit two birds with one stone appealing both to people worried about the environment and those looking for something easy to clean and maintain. Recent industry reports show that waterproof floor options are becoming really popular these days, with some estimates suggesting they might account for nearly half of all home flooring purchases soon. What makes this interesting is how well these products balance what people actually need day to day with their growing concern about sustainability issues affecting our planet.

Circular Economy Initiatives in SPC Production

Take-Back Programs for Manufacturing Offcuts

Recycling programs are becoming increasingly important for dealing with waste from SPC flooring manufacturing operations. When companies set up these take-back systems, they actually make it easier for old materials to get recycled instead of ending up in landfills. For manufacturers looking at their bottom line, such programs help save money on raw materials while also preserving natural resources. Plus, having a good recycling program looks great on company sustainability reports. Some studies indicate that businesses running solid take-back schemes manage to slash their leftover material waste by around 80 percent, which makes a huge difference over time both environmentally and financially.

Closed-Loop Material Recovery Systems

Material recovery systems that work in a closed loop play a key role when it comes to recycling SPC Flooring after it reaches the end of its useful life. With these systems in place, manufacturers can take apart old flooring products and reuse their core components rather than sending everything to landfills. The result? Less need for brand new raw materials like PVC and wood flour, which makes production more sustainable overall. For flooring companies looking to cut expenses while being environmentally responsible, this kind of system offers real advantages. Some studies indicate that businesses implementing closed-loop approaches might see their material expenses drop somewhere around 25-30%, depending on how well they integrate recovered materials back into their manufacturing processes.

Recycling Compatibility with Existing PVC Infrastructure

How well SPC Flooring works with existing PVC recycling systems matters a lot when it comes to actually processing and reusing the material. When flooring products can fit into standard recycling streams, factories are more likely to want them on their production lines. The fact that these floors play nicely with recycling processes helps position them right where the industry needs to be heading for greener operations. Some studies have shown that getting this compatibility right could boost recycling rates for flooring materials anywhere from 40 to 50 percent. That kind of improvement makes a real difference in waste reduction efforts across manufacturing sectors.

Competitive Positioning Against Alternative Flooring

Performance Advantages Over Traditional LVT

Many homeowners and business owners are turning to SPC Flooring because it stands up better to wear and tear than regular Luxury Vinyl Tile (LVT). The product really shines in places with lots of foot traffic, like office buildings or busy retail spaces, since it can handle constant movement without breaking down. What sets SPC apart is its solid core construction. This gives the floor extra protection against drops and heavy furniture, while also preventing those annoying dents that plague other flooring options. Recent sales figures show SPC Flooring growing faster than LVT in most regions, probably because people actually want something that lasts longer between replacements. With all these practical benefits, it's no surprise that SPC has become one of the top contenders in today's competitive flooring market.

Cost Comparisons with Engineered Wood and Laminate

Looking at the bottom line when comparing SPC flooring to options like engineered wood and laminate, most people find SPC comes out ahead after a few years. Sure, it might cost a bit more upfront to install, but think about all the money saved on repairs and replacements down the road. The stuff just lasts longer without needing constant attention. Some studies have shown that over ten years, SPC tends to run around 20 percent less expensive overall than similar products on the market. For folks watching their wallets while still wanting quality floors, this makes SPC pretty attractive despite the initial price tag.

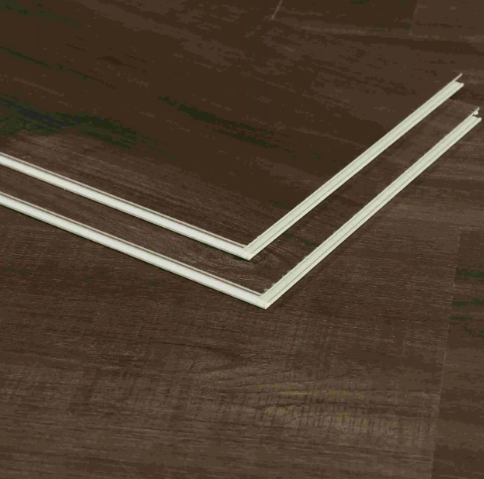

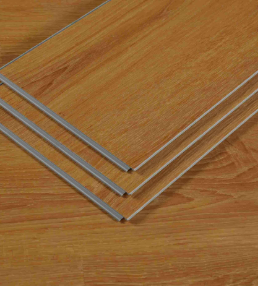

Multi-Layer Construction Standards Evolution

Changes in how we build multi layer SPC flooring have really boosted both how well it performs and looks good too. The new methods let designers play around with all sorts of styles that appeal to different people. Some folks want something fancy for their homes while others need tough stuff for businesses. According to what the industry folks are saying, floors made using these better building techniques actually sell for about 15 percent more in the market place. What this means is that besides being functional, SPC flooring now stands out against competitors because it meets what customers want and often goes beyond those basic requirements.

Installation Innovations and Commercial Applications

Click-Lock Systems Enabling DIY Adoption

Click lock systems have really changed how people install SPC flooring, and they're a hit with folks who love doing their own home projects. What makes these systems so great? They eliminate sticky glues altogether, which means installations go much quicker and leave behind fewer messes. Most homeowners find they only need basic hand tools like a mallet and maybe a saw for corners. According to recent market research, around three out of four homeowners actually prefer flooring options where they don't have to call in professionals. Beyond saving money on labor fees, there's something satisfying about seeing a project through from start to finish. Plus, DIY installation gives people more control over colors and patterns throughout their living spaces.

Healthcare and Education Sector Specifications

SPC Flooring has become really popular lately in places like hospitals and schools because it combines durability with the need for clean surfaces. Healthcare facilities especially appreciate how this flooring stands up to constant cleaning while still looking good over time. Most commercial buildings need to follow strict regulations about materials used indoors, and SPC Flooring checks all those boxes for safety and health requirements. Some studies show that when schools and medical centers switch to SPC Flooring, they end up spending around 40 percent less on maintenance work since the floors don't get damaged easily and are simple to keep clean. For institutions worried about keeping costs down without sacrificing sanitation standards, this type of flooring makes a lot of sense from both practical and budgetary perspectives.

Acoustic Performance Enhancements

The better sound control features of SPC flooring really boost its popularity across homes and offices alike because they block out unwanted noise so effectively. People want quieter places to live and work these days, which has led manufacturers to come up with new underlay materials that cut down on floor vibrations and echoes even more. According to recent market research, around two thirds of business customers actually care quite a bit about how well floors handle sound when choosing what kind to install. This focus on acoustics means SPC flooring works great not just in apartments or houses but also in schools, hospitals, and office buildings where keeping things quiet matters a lot.

Future Market Forecast and Investment Hotspots

Projected 6.8% CAGR Through 2035

The SPC flooring market looks set to grow steadily over the next decade, with estimates pointing toward around 6.8% compound annual growth by 2035. Construction activity and home renovations continue to drive interest in these flooring solutions, especially since people want something that lasts but still looks good in their spaces. What's really pushing things forward? New designs hitting the shelves and better manufacturing techniques that make production more efficient. Most industry watchers agree that the real action will happen in developing regions as cities expand quickly and infrastructure needs increase dramatically across these markets.

Smart Factory Expansions in Vietnam and India

Vietnam and India are seeing big money poured into smart factory tech for SPC Flooring manufacturing right now. These expansion projects fit right into what's happening globally with factories getting smarter through automation and digital tools. The companies behind this aren't just talking either they actually expect better prices because of lower costs per unit plus higher product quality across the board. Industry analysts are looking at some pretty impressive numbers too, suggesting production might jump around 30% in five years if everything goes according to plan. That kind of growth would definitely shake things up in how SPC Flooring operates on the world stage, especially when it comes to where materials come from and where finished products go next.

Luxury Segment Penetration Strategies

Focusing on the luxury side of the SPC flooring market opens up some really good opportunities for businesses looking to stand out from competitors. To break into this upscale territory, companies typically focus on three main areas: better design choices, top quality finishes, and eco friendly production methods that catch the eye of customers who know what they want. According to recent industry data, the luxury SPC segment seems to be growing at around 12% per year, which beats the average growth rate across the entire market. What this means is that manufacturers need to keep coming up with new ideas if they want to satisfy those premium buyers who are always chasing something special when it comes to flooring options. The market clearly shows there's room for innovation in creating products that deliver both style and substance for discerning clients.

FAQ

What is SPC flooring?

SPC stands for Stone Plastic Composite, which is a type of rigid core flooring that combines limestone powder and PVC to create durable flooring solutions.

Why is SPC flooring gaining popularity?

SPC flooring is popular due to its durability, waterproof properties, cost efficiency, and design versatility, making it suitable for both residential and commercial applications.

How does SPC flooring compare to traditional hardwood?

SPC flooring mimics the appearance of hardwood at a lower cost while offering superior waterproof and impact-resistant properties.

Is SPC flooring environmentally friendly?

SPC flooring can be environmentally friendly, especially with advancements in using bio-based PVC, recycled limestone formulations, and ESG-compliant manufacturing processes.

Table of Contents

-

SPC Flooring Market Growth Trajectory and Key Drivers

- Global SPC Flooring Market Valuation Projections

- Residential vs. Commercial Adoption Patterns

- Asia-Pacific Dominance in Production and Consumption

- Technological Innovations Reshaping SPC Flooring Trends

- Digital Emboss-in-Register Printing for Hyper-Realistic Textures

- Thinner, High-Strength Core Designs Reducing Carbon Footprint

- Integrated Radiant-Heat Film Systems

- Sustainability as a Market Differentiator

- Bio-Based PVC and Recycled Limestone Formulations

- ESG-Compliant Manufacturing Processes

- Waterproof Performance Enhancing Durability

- Circular Economy Initiatives in SPC Production

- Take-Back Programs for Manufacturing Offcuts

- Closed-Loop Material Recovery Systems

- Recycling Compatibility with Existing PVC Infrastructure

- Competitive Positioning Against Alternative Flooring

- Performance Advantages Over Traditional LVT

- Cost Comparisons with Engineered Wood and Laminate

- Multi-Layer Construction Standards Evolution

- Installation Innovations and Commercial Applications

- Click-Lock Systems Enabling DIY Adoption

- Healthcare and Education Sector Specifications

- Acoustic Performance Enhancements

- Future Market Forecast and Investment Hotspots

- Projected 6.8% CAGR Through 2035

- Smart Factory Expansions in Vietnam and India

- Luxury Segment Penetration Strategies

- FAQ