Core Composition: SPC's Limestone Core vs. PVC's Flexible Vinyl

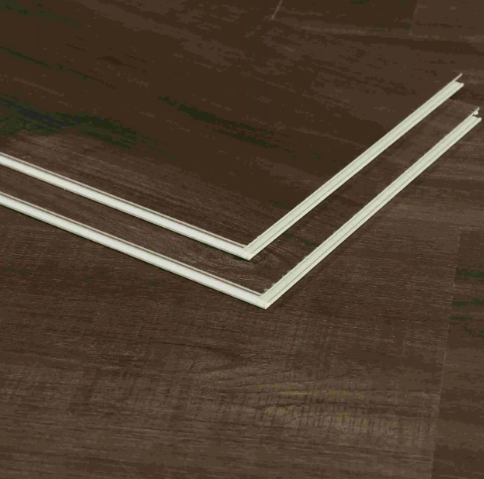

SPC's Stone Plastic Composite Structure

Stone Plastic Composite flooring, commonly called SPC, gets its name from the mix of crushed stone and plastic materials that form its base. What makes SPC different from regular vinyl floors? Its solid construction gives it extra stiffness and strength right out of the box. Most SPC products have around 60% limestone mixed with 40% PVC plus some additives to keep everything stable. This particular combination creates a floor surface that holds up much better against daily wear and tear than traditional vinyl options. Homeowners love how the limestone core fights off scratches and dents while resisting water damage too. Commercial property managers are catching on fast because these floors stay looking good even after years of constant foot traffic. We've seen them installed everywhere from busy office buildings to family kitchens where they just keep going strong season after season. No wonder demand keeps rising across global markets despite all the competition out there.

PVC Flooring's All-Vinyl Construction

PVC flooring gets its name from Polyvinyl Chloride, basically a type of synthetic plastic that serves as the main component in most vinyl flooring products. What makes PVC special is how it's built in several distinct layers, each doing something specific to give the floor both flexibility and comfort when walked on. Most installations have a protective top layer first, then comes the printed design layer where manufacturers put their creative touches, and underneath all that are multiple vinyl layers that help keep everything flexible. The way these layers work together means PVC floors can handle various situations pretty well, offering a noticeably softer feel underfoot than SPC alternatives. Flooring professionals often point out that this layered approach gives better insulation against cold and also helps dampen noise because the material absorbs sound instead of letting it bounce around. That's why many homeowners find PVC especially appealing for living areas and bedrooms. Sure, it doesn't have the same solid feel as some composite options out there, but folks who care more about walking comfort and staying warm during winter months tend to prefer PVC over stiffer materials.

Material Density Comparison

The difference in density between SPC and PVC flooring really matters when looking at how long they last and how well they block noise. SPC has this dense stone plastic composite core that clocks in around 2 grams per cubic centimeter, whereas regular PVC sits closer to 1.4 grams per cubic centimeter. Because SPC is so much denser, it stands up better to wear and tear while also doing a better job at keeping sounds contained. Industry experts note that this density lets SPC handle heavier loads too, which means less noise bouncing between floors in apartment complexes or office buildings. Another plus point for dense materials is their ability to spread heat more evenly across floors when paired with underfloor heating systems. This makes rooms warmer faster and keeps energy bills lower over time. Knowing all this helps people pick the right floor type depending on what they need most from their space, whether it's quiet living conditions, good looks, or just staying cozy during winter months.

Key Performance Differences

Dimensional Stability in Temperature Fluctuations

When it comes to handling temperature changes, SPC flooring stands out from regular PVC flooring in terms of staying stable. While PVC tends to buckle when exposed to extreme heat or cold, SPC keeps its shape pretty well. The reason behind this lies in the stone plastic composite core inside SPC planks, which cuts down on expansion issues that typically lead to warping problems. Research backs this up too, showing how SPC performs reliably even when conditions shift around, whereas standard PVC floors often struggle. For places where temperatures fluctuate throughout the day, like warehouses or homes near industrial areas, SPC becomes the go-to option because it just doesn't play favorites with climate changes. Both homeowners and business owners have noticed this difference over time, making SPC increasingly popular despite higher initial costs.

Impact Resistance: Furniture & Heavy Traffic

SPC flooring really shines when we talk about how well it handles impacts. The rigid composite core gives it serious staying power against dents and pressure points. Drop tests have shown time and again that SPC holds up much better than regular PVC flooring under similar conditions. Lab results actually give SPC higher impact resistance scores, which means it can take a beating in places where furniture gets moved around a lot or where people are constantly walking back and forth. For anyone looking at installation options, this translates to excellent performance in real life situations like retail stores, offices, or even homes with kids and pets running through them day after day.

Moisture Tolerance & Waterproof Capabilities

SPC flooring stands out because it won't soak up water, which makes it great for places where moisture is always an issue, think bathrooms and kitchens especially. The way these floors are built with a solid core means they take in far less water than regular PVC options that just seem to drink it up. Industry tests have shown this works in practice too, with SPC showing much better resistance to water damage over time. Homeowners who've installed SPC in their wet areas report fewer problems with warping or buckling even after years of exposure. For anyone dealing with constant dampness issues, these waterproof properties really make a difference in keeping floors looking good without needing constant repairs or replacements.

Underfoot Feel & Acoustic Properties

SPC's Rigid Surface Characteristics

SPC flooring has that solid feel underfoot because of how hard the surface actually is. People who stand on it all day might find their feet getting sore pretty quickly, so it doesn't really work well in homes where folks want something softer to walk on. Most folks who install SPC talk about how tough it holds up in busy places like stores or offices that see constant foot traffic. The downside though? All that stiffness means it doesn't quiet down noises very well at all. The thick core just doesn't soak up sounds from footsteps or dropped items like other materials would. That could be a real problem in apartments or anywhere else where keeping noise levels down matters a lot.

PVC's Flexible Comfort Advantages

What makes PVC flooring so popular? Well, its flexibility definitely stands out as a big plus. People actually find it much more comfortable to walk on compared to other options, especially in homes. The material bends a bit when stepped on, which helps take pressure off feet after standing around all day. Many homeowners report feeling less tired at the end of the day because their floors aren't so hard on them. Most folks who have tried both PVC and SPC flooring will tell you they prefer the softer feel of PVC in living areas or bedrooms where they spend a lot of time barefoot. There's just something about walking on a floor that gives just enough give without being too squishy that feels right for home use.

Noise Reduction Capabilities Compared

Looking at how SPC and PVC flooring handle sound, SPC generally has a thicker, denser core that absorbs sounds better than most PVC options on the market today. Because of this density, SPC does a much better job reducing those annoying footstep noises, which makes it particularly good for places like apartment complexes or office buildings where people want their floors to be quiet between floors. Real world tests and what actual users report consistently show that SPC outperforms PVC when it comes to keeping noise contained within rooms. While PVC might feel softer underfoot and offer some comfort advantages, there's no denying that SPC's ability to cut down on unwanted noise makes all the difference in certain situations, especially in commercial spaces or residential units above ground level.

Installation Methods Compared

SPC Floating Floor Systems

Installing SPC flooring with floating floor systems has become pretty straightforward these days. One big plus is that there's no need for glue or messy adhesives, which makes the whole process much cleaner and faster than older methods. That's why so many people who love doing their own home projects find this approach so appealing. What really stands out about these floating systems is how fast they go down. The planks just click together, and before long, an entire room can be covered without much hassle at all. Traditional installations would have required weeks of prep work, but with SPC's rigid construction, minor flaws in the existing floor underneath get hidden away automatically. This not only speeds things up during installation but also means better results in the long run when it comes to how the floor performs day after day.

PVC Adhesive Requirements

Installing PVC flooring comes with certain requirements, especially when it comes to picking the right adhesive. How well the adhesive sticks matters a lot for how long the floor will last and stay stable over time. Good bonding is important but getting the wrong kind or applying it improperly can cause problems down the road. Applying adhesive properly isn't always easy either since it tends to be messy work that many homeowners find daunting. Most professionals recommend going for quality adhesives that match what kind of PVC flooring someone has installed. This approach helps make sure everything holds up better and reduces headaches later on when dealing with floors that don't stick properly.

Subfloor Preparation Differences

Getting the subfloor ready makes all the difference when installing SPC versus PVC floors, since each material needs different prep work to perform well. SPC has a stiffer composition so it actually requires less aggressive leveling and moisture checks than what's needed for PVC installations. But don't skip these steps for PVC at all because without proper leveling and checking for dampness, the floor can buckle or move around after installation. Taking time to prepare the subfloor correctly pays off in the long run though. Both types last longer and stay looking good when installed properly, which is exactly what most homeowners want from their investment in new flooring.

Durability & Long-Term Maintenance

Wear Layer Performance in High-Traffic Areas

The wear layer really matters when it comes to how long SPC and PVC floors last, particularly in places with lots of people walking over them all day. For SPC floors, we're talking about wear layers that measure somewhere between 0.3mm and 0.5mm thick. That gives pretty good defense against scratches and scuff marks from everyday use. No wonder why so many businesses opt for SPC in their stores or offices where hundreds pass through daily. With PVC flooring things get a bit different since the wear layer can be thinner, sometimes as low as 0.2mm depending on what brand or model someone picks. Practical experience tells us that SPC tends to hold up better visually over time in busy spots such as retail centers or educational institutions compared to regular PVC options. The thicker coating on SPC just doesn't dent as easily and stands up to aging much better than thinner alternatives, which explains why these floors tend to stick around longer without looking worn out.

Scratch Resistance Comparison

When looking at how resistant flooring is to scratches, it really matters for floors that get used all day long in homes and businesses alike. SPC flooring tends to do better in these tests because of what it's made of and that extra protective layer on top. This makes it stand up much better against normal stuff like people walking around or dragging chairs across the floor. Most testing organizations give SPC higher marks for scratch resistance than they do for PVC flooring, which just doesn't hold up as well when it comes to those little marks and scrapes. At home, things like moving couches or pet claws can leave their mark, whereas offices and stores deal with constant foot traffic and all sorts of equipment being dragged back and forth. People who actually install and live with these floors report that SPC keeps looking good for years, with way less damage showing up compared to those cheaper PVC alternatives out there.

Expected Lifespan in Residential vs Commercial Use

Knowing how long SPC and PVC flooring last matters a lot when figuring out what makes sense over time, especially depending where they're installed. SPC tends to hold up really well, lasting anywhere from 15 to 20 years in homes and sometimes even longer in places like stores or office buildings because it's built tough. Flooring professionals keep coming back to this point about durability being a big plus, which is why many businesses install it in busy spots such as shopping centers and corporate lobbies. PVC options generally don't last quite as long though, usually giving about 10 to 15 years before showing wear, but that can vary based on how well someone takes care of them and whether they were properly laid down initially. Property owners who have experience with both materials often tell stories about SPC standing up against everything thrown at it without breaking down much. They also stress that getting good results requires proper installation first off, followed by regular cleaning and maintenance practices for either type of floor.

Choosing Between SPC and PVC Flooring

Best Applications for SPC's Strengths

SPC flooring works great in homes and businesses because it's tough and holds its shape well. People often suggest using it in places where water gets around a lot like kitchens, bathrooms, maybe even basements since it doesn't get damaged by moisture so easily. Most folks who work with flooring say the strength and water resistant base of SPC makes sense for these kinds of spots. We've seen plenty of real world examples where this type of flooring holds up in busy areas that need something durable. It just keeps going without showing wear and tear, which is exactly what many commercial spaces are looking for when they want something that lasts.

When to Prioritize PVC Flexibility

Flexible PVC flooring works really well when we need something that can bend to different design needs while still feeling good underfoot. Think about places like kids' play areas or senior care centers where people want some give in the floor instead of hard tile or wood. The material bends and stretches during installation, which means designers can get pretty creative with patterns and shapes without worrying about cracks forming later on. We've seen this type of flooring make a big difference in nursing homes specifically because it reduces fall risks for residents who might otherwise slip on harder surfaces. Plus, those little bumps and grooves in the pattern actually help with drainage in bathrooms and kitchens too.

Budget Considerations & ROI Analysis

Budget is always a big factor when picking between SPC and PVC floors. People need to think about what they pay upfront versus what they save later on. SPC tends to cost more at first because it lasts longer and stands up better to water damage, which means fewer repairs down the road and potentially boosts property values in the long run. PVC flooring comes in at a lower price point while still offering lots of style choices, so many folks who watch their spending find this option attractive. Real estate experts have noticed that good quality flooring makes a real difference in home value, so knowing this helps homeowners get their money's worth. Looking at both options side by side reveals different pros and cons regarding durability, looks, and wallet impact. Homeowners should consider these factors carefully before making a decision based on what matters most to them personally.

FAQ Section

What is SPC flooring?

SPC flooring stands for Stone Plastic Composite flooring. It is composed of stone powder and polymer resins, providing durability and stability with a rigid and strong core.

What are the key differences between SPC and PVC flooring?

The main difference is the composition. SPC flooring uses a stone plastic composite core with high density, offering better impact resistance and waterproof capabilities. PVC flooring is all vinyl, providing more flexibility, comfort, and thermal insulation.

Is SPC flooring suitable for residential spaces?

Yes, SPC flooring is ideal for areas with heavy traffic and moisture exposure, not as comfortable as PVC flooring. It excels in commercial settings due to its strength and durability.

Can PVC flooring be used in kitchens and bathrooms?

While PVC flooring is flexible, it is more prone to moisture absorption compared to SPC flooring, making SPC the better choice for moisture-prone areas like kitchens and bathrooms.