Modern homeowners face significant challenges when selecting flooring for moisture-prone areas like kitchens and bathrooms. Traditional flooring materials often fail under constant exposure to water, humidity, and temperature fluctuations. Waterproof vinyl flooring has emerged as the premier solution for these demanding environments, offering unmatched durability and aesthetic versatility. This innovative flooring technology combines advanced manufacturing techniques with practical design elements to create surfaces that withstand the rigors of daily moisture exposure while maintaining their appearance and structural integrity.

Understanding Waterproof Vinyl Flooring Technology

Advanced Core Construction Methods

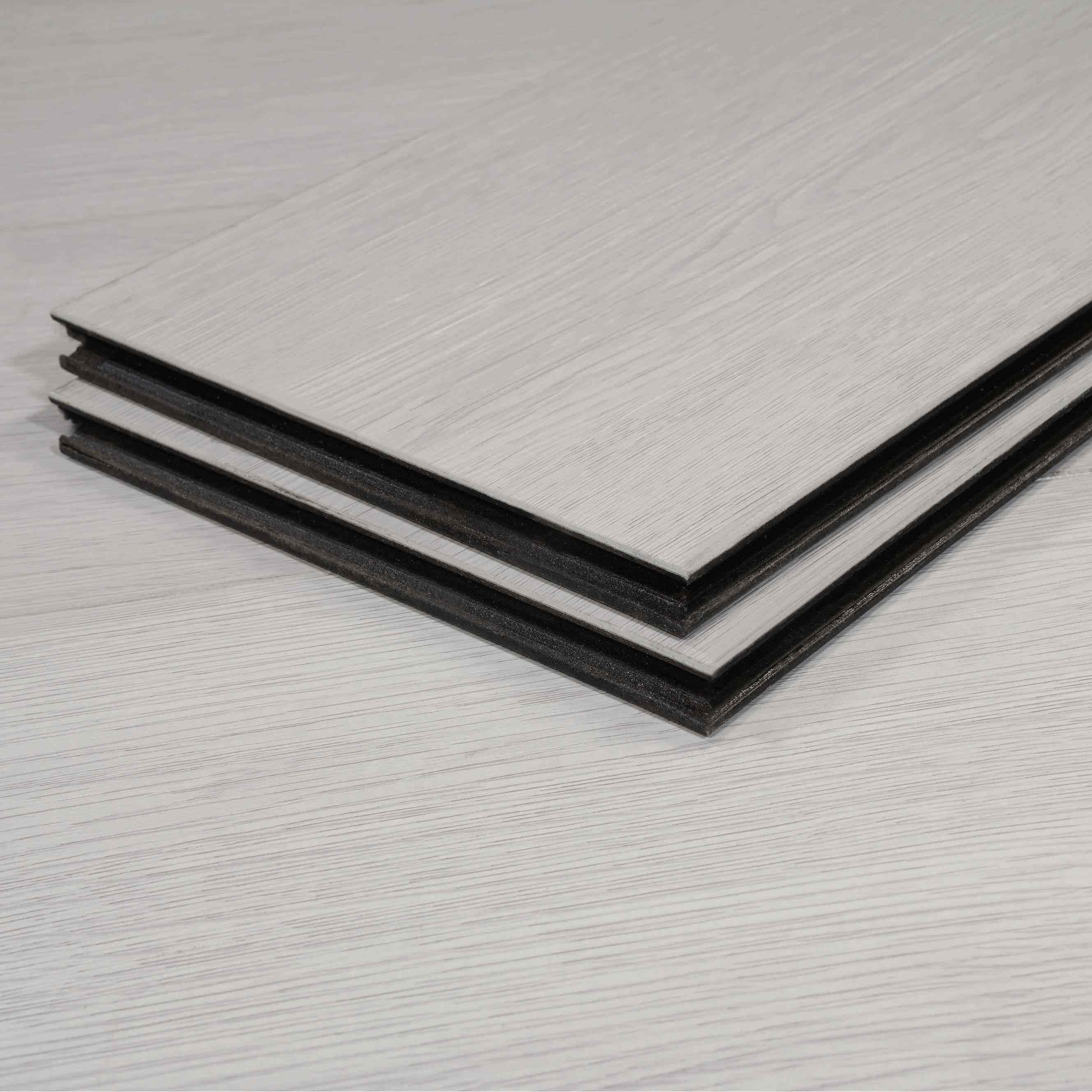

Waterproof vinyl flooring utilizes sophisticated core technologies that fundamentally differ from conventional vinyl products. The rigid core construction incorporates stone plastic composite materials that create an impermeable barrier against moisture penetration. These cores combine limestone powder, polyvinyl chloride, and plasticizers to form a dimensionally stable foundation that resists expansion and contraction under varying moisture conditions. The manufacturing process involves high-pressure lamination techniques that eliminate air pockets and create seamless bonds between layers.

The protective wear layer on waterproof vinyl flooring features advanced urethane coatings that provide both moisture resistance and surface durability. This transparent layer undergoes specialized curing processes that create molecular-level bonds with the decorative layer beneath. The result is a surface that repels water while maintaining scratch resistance and UV stability. Modern formulations incorporate antimicrobial additives that prevent bacterial growth and maintain hygienic conditions in moisture-rich environments.

Innovative Installation Systems

Contemporary waterproof vinyl flooring systems feature click-lock mechanisms that create watertight seals between planks without requiring adhesives. These interlocking systems utilize precision-engineered tongue and groove profiles that compress upon installation to form continuous moisture barriers. The mechanical locking systems allow for floating installation methods that accommodate substrate movement while maintaining waterproof integrity. Some advanced systems incorporate additional sealing compounds applied to joint areas for enhanced protection.

The installation flexibility of waterproof vinyl flooring extends to substrate preparation requirements. These products can be installed over concrete, plywood, existing vinyl, and even ceramic tile surfaces when proper preparation procedures are followed. The built-in moisture protection eliminates the need for separate vapor barriers in most applications. This installation efficiency reduces project timelines and labor costs while ensuring long-term performance in demanding environments.

Performance Benefits in Kitchen Environments

Moisture Resistance and Spill Management

Kitchen environments present unique challenges for flooring materials due to constant exposure to cooking moisture, food spills, and cleaning activities. Waterproof vinyl flooring addresses these challenges through its impermeable surface structure that prevents liquid penetration into the flooring system. The seamless installation methods eliminate grout lines and seams that typically allow moisture infiltration in ceramic tile installations. This comprehensive moisture protection extends to areas around kitchen islands, sinks, and appliance locations where water exposure is most frequent.

The surface texture variations available in waterproof vinyl flooring provide appropriate slip resistance for kitchen safety while maintaining easy cleaning characteristics. Embossed textures and registered surface patterns create visual depth without creating cleaning difficulties. The non-porous surface structure resists staining from common kitchen substances including oils, acidic foods, and colored liquids. This stain resistance maintains the flooring appearance throughout years of kitchen use without requiring special maintenance procedures.

Temperature Stability and Thermal Performance

Kitchen environments experience significant temperature variations from cooking activities, appliance operation, and seasonal changes. Waterproof vinyl flooring demonstrates exceptional dimensional stability across wide temperature ranges without exhibiting expansion gaps or contraction issues. The rigid core construction maintains consistent plank dimensions even when subjected to radiant heat from appliances or underfloor heating systems.

The thermal conductivity properties of waterproof vinyl flooring support comfortable kitchen environments while maintaining energy efficiency. The material structure provides appropriate insulation values without creating cold spots or temperature variations across the floor surface. This thermal consistency contributes to overall kitchen comfort while supporting efficient heating and cooling system operation. The material compatibility with radiant heating systems makes waterproof vinyl flooring suitable for modern kitchen designs incorporating underfloor heating technology.

Bathroom Application Advantages

Humidity Control and Moisture Management

Bathroom environments create some of the most challenging conditions for flooring materials through constant humidity exposure, direct water contact, and temperature fluctuations from bathing activities. Waterproof vinyl flooring provides comprehensive protection against these conditions through its engineered barrier properties. The material structure prevents humidity absorption that typically causes swelling, warping, and degradation in traditional flooring materials. The surface design incorporates drainage patterns and textures that facilitate water removal while preventing accumulation in low areas.

The antimicrobial properties integrated into waterproof vinyl flooring formulations actively resist mold and mildew growth in bathroom environments. These protective additives maintain their effectiveness throughout the product lifespan without requiring periodic reapplication. The smooth surface characteristics prevent bacterial accumulation while supporting thorough cleaning procedures. This hygienic performance makes waterproof vinyl flooring particularly suitable for family bathrooms and high-use facilities where cleanliness standards are paramount.

Design Flexibility and Aesthetic Options

Modern waterproof vinyl flooring collections offer extensive design possibilities that accommodate diverse bathroom styling preferences. High-definition printing technologies create realistic wood grain patterns, stone textures, and ceramic appearances that provide authentic visual appeal. The color stability of these printed surfaces maintains consistent appearance under bathroom lighting conditions including natural daylight and artificial illumination. The wide plank formats available in waterproof vinyl flooring support contemporary design trends while providing practical installation advantages.

The customization options for waterproof vinyl flooring extend to edge profiles, surface textures, and installation patterns that create unique bathroom environments. Mixed-width installations, herringbone patterns, and diagonal layouts provide design flexibility while maintaining waterproof performance. The material compatibility with bathroom fixtures and cabinetry allows for seamless integration with existing design elements. This design versatility makes waterproof vinyl flooring suitable for both renovation projects and new construction applications.

Installation Considerations and Best Practices

Substrate Preparation Requirements

Successful waterproof vinyl flooring installation requires attention to substrate conditions that affect long-term performance. The subfloor must provide a stable, level surface that meets manufacturer tolerance specifications for height variations. Concrete substrates require moisture testing to ensure compatibility with the flooring system even though waterproof vinyl flooring provides inherent moisture protection. Proper substrate preparation includes addressing any structural issues, leveling compound application where necessary, and thorough cleaning to remove construction debris.

The acclimation procedures for waterproof vinyl flooring vary by product type and environmental conditions. Rigid core products typically require minimal acclimation periods compared to traditional vinyl materials. However, maintaining consistent temperature and humidity conditions during installation ensures optimal performance. The installation environment should be controlled to manufacturer specifications throughout the project timeline. This environmental control supports proper material handling and ensures mechanical locking systems function correctly during assembly.

Professional Installation Techniques

Professional installation of waterproof vinyl flooring incorporates specific techniques that maximize the moisture protection capabilities of the system. Starting wall selection affects the overall appearance and requires consideration of room dimensions and architectural features. The expansion gap requirements for waterproof vinyl flooring account for the minimal thermal movement characteristics of rigid core products. Proper cutting techniques using appropriate tools ensure clean edges that maintain the waterproof integrity of the installation.

The transition methods used with waterproof vinyl flooring must maintain moisture protection while accommodating different flooring materials in adjacent areas. Specialized transition strips and molding systems provide seamless connections to ceramic tile, hardwood, and carpet installations. The installation sequence around fixed objects like toilet flanges and cabinet bases requires careful planning to maintain continuous moisture barriers. These professional techniques ensure that the waterproof vinyl flooring system performs as designed throughout its service life.

Long-term Maintenance and Care

Daily Cleaning Procedures

The maintenance requirements for waterproof vinyl flooring emphasize simple cleaning procedures that preserve both appearance and performance characteristics. Daily cleaning involves dry mopping or vacuuming to remove surface debris without using harsh cleaning tools that might damage the wear layer. The smooth surface texture of waterproof vinyl flooring facilitates efficient cleaning while preventing dirt accumulation in surface irregularities. Regular cleaning maintains the hygienic properties of the flooring while supporting its aesthetic appeal.

Wet cleaning procedures for waterproof vinyl flooring utilize pH-neutral cleaning solutions that maintain the integrity of the protective surface layers. The waterproof characteristics allow for thorough mopping without concerns about moisture damage to the flooring system. Steam cleaning methods can be employed periodically for deep sanitation without affecting the dimensional stability of the material. The cleaning chemical compatibility of waterproof vinyl flooring supports the use of standard household cleaning products without special restrictions.

Periodic Maintenance Requirements

Long-term maintenance of waterproof vinyl flooring focuses on preserving the wear layer integrity and maintaining the appearance characteristics. Periodic deep cleaning using manufacturer-approved products removes accumulated residues that might affect surface appearance. The inspection procedures for waterproof vinyl flooring installations include checking transition areas and perimeter installations for proper seal maintenance. Any gaps or separations require prompt attention to maintain the moisture protection capabilities of the system.

The refinishing options for waterproof vinyl flooring are limited compared to traditional hardwood products, making proper initial care essential for longevity. However, the durability characteristics of modern waterproof vinyl flooring formulations provide decades of service life with appropriate maintenance. The replacement procedures for individual planks allow for localized repairs without affecting the entire installation. This repairability makes waterproof vinyl flooring a practical long-term flooring solution for kitchen and bathroom applications.

FAQ

How does waterproof vinyl flooring differ from water-resistant vinyl products?

Waterproof vinyl flooring provides complete moisture protection through its core construction and installation methods, while water-resistant products offer limited protection against surface moisture only. True waterproof vinyl flooring utilizes rigid cores that prevent moisture penetration and dimensional changes, whereas water-resistant varieties may still allow moisture infiltration through seams and edges. The installation systems for waterproof vinyl flooring create continuous moisture barriers that water-resistant products cannot achieve through their construction methods.

Can waterproof vinyl flooring be installed in areas with underfloor heating systems?

Most waterproof vinyl flooring products are compatible with radiant heating systems when installed according to manufacturer specifications. The thermal conductivity properties of rigid core waterproof vinyl flooring support efficient heat transfer while maintaining dimensional stability. However, temperature limitations must be observed to prevent damage to the wear layer and adhesive systems. Professional installation ensures proper thermal barriers and temperature monitoring systems are incorporated for optimal performance with underfloor heating applications.

What tools are required for waterproof vinyl flooring installation?

Standard installation of waterproof vinyl flooring requires basic carpentry tools including measuring devices, cutting tools, and tapping blocks for the locking mechanisms. Specialized cutting tools such as vinyl plank cutters or fine-tooth saws provide clean cuts that maintain the waterproof integrity of edge seals. Installation kits typically include spacers, pull bars, and installation wedges specific to the locking system design. Power tools like miter saws can expedite cutting procedures while ensuring precision fits around obstacles and transitions.

How long does waterproof vinyl flooring typically last in high-moisture environments?

Quality waterproof vinyl flooring installations provide 20-25 years of service life in kitchen and bathroom environments when properly maintained. The wear layer thickness and core construction quality directly affect longevity, with commercial-grade products offering extended service life compared to residential formulations. Environmental factors such as temperature extremes, cleaning chemical exposure, and traffic patterns influence actual service life. Manufacturer warranties typically provide 10-15 year coverage for residential applications, indicating confidence in long-term performance under normal use conditions.

Table of Contents

- Understanding Waterproof Vinyl Flooring Technology

- Performance Benefits in Kitchen Environments

- Bathroom Application Advantages

- Installation Considerations and Best Practices

- Long-term Maintenance and Care

-

FAQ

- How does waterproof vinyl flooring differ from water-resistant vinyl products?

- Can waterproof vinyl flooring be installed in areas with underfloor heating systems?

- What tools are required for waterproof vinyl flooring installation?

- How long does waterproof vinyl flooring typically last in high-moisture environments?