Selecting the right waterproof vinyl flooring for your space requires careful consideration of multiple factors that directly impact performance, durability, and long-term satisfaction. Modern waterproof vinyl flooring has revolutionized residential and commercial flooring solutions by offering superior moisture resistance while maintaining aesthetic appeal and practical functionality. Understanding the key characteristics that distinguish high-quality waterproof vinyl flooring from inferior alternatives empowers property owners to make informed decisions that protect their investment and enhance their living or working environments.

Core Construction Features of Quality Waterproof Vinyl Flooring

Multilayer System Architecture

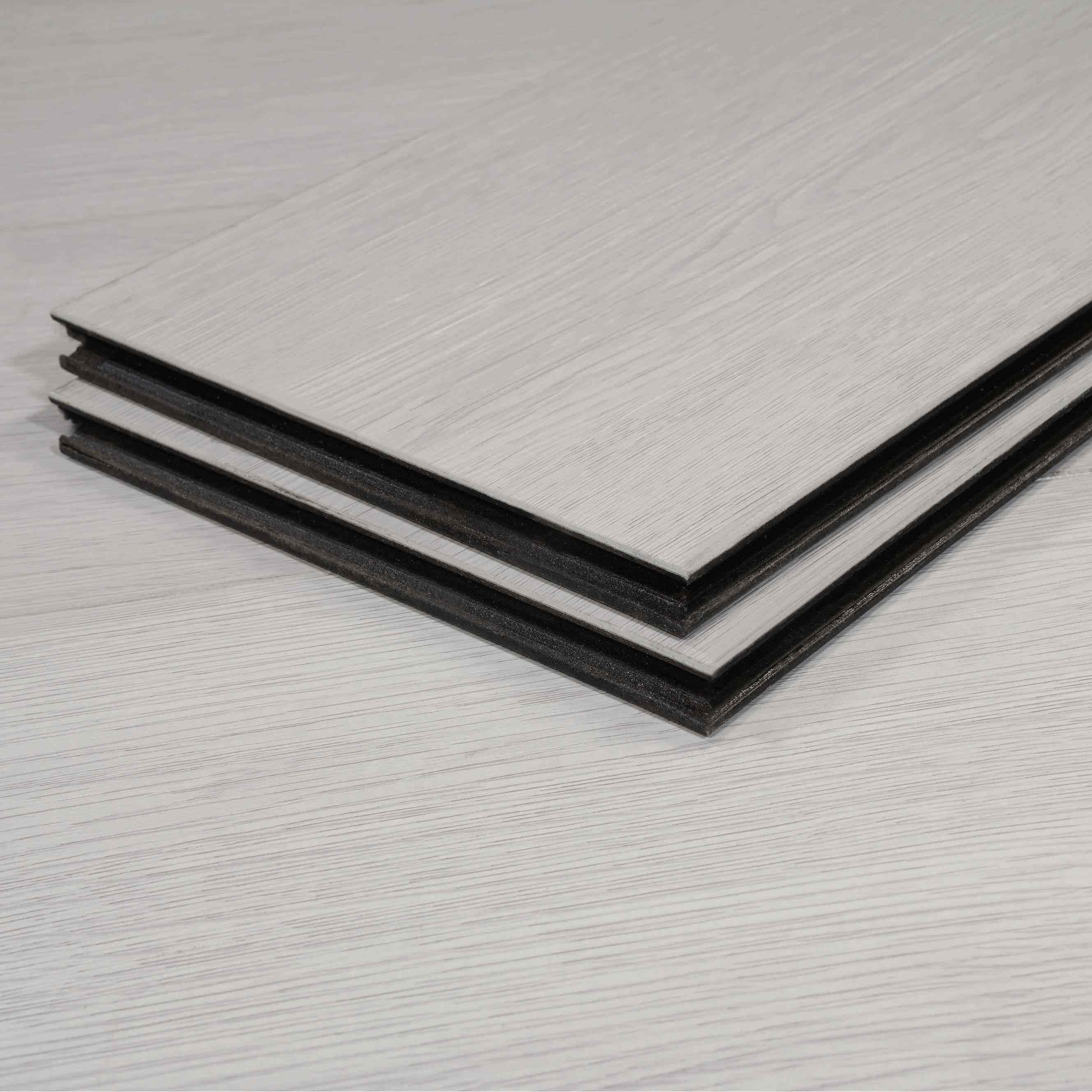

The foundation of exceptional waterproof vinyl flooring lies in its sophisticated multilayer construction system that provides comprehensive protection against moisture infiltration. Premium waterproof vinyl flooring typically incorporates a rigid core layer, often composed of stone plastic composite materials that resist expansion and contraction under varying temperature and humidity conditions. This core layer serves as the structural backbone, ensuring dimensional stability while supporting the decorative surface layer above. The wear layer, positioned as the topmost component, determines scratch resistance and overall durability, with thickness measurements directly correlating to the flooring's ability to withstand heavy traffic and daily wear patterns.

Advanced waterproof vinyl flooring systems integrate specialized underlayment layers that enhance acoustic performance while providing additional moisture barriers. These integrated backing systems eliminate the need for separate underlayment installation, reducing labor costs and potential installation errors that could compromise waterproof integrity. The seamless integration of these layers creates a unified flooring system that performs consistently across diverse environmental conditions, making it suitable for kitchens, bathrooms, basements, and commercial applications where moisture exposure is inevitable.

Waterproof Technology Integration

Modern waterproof vinyl flooring employs sophisticated sealing technologies that prevent water penetration through both surface absorption and edge infiltration. Edge sealing mechanisms utilize precision-engineered locking systems that create watertight connections between individual planks or tiles, preventing moisture from seeping through seam lines. This technology is particularly crucial in areas prone to spills or standing water, where traditional flooring materials might experience warping, buckling, or delamination over time.

The surface treatment of quality waterproof vinyl flooring incorporates advanced polymer coatings that repel liquids while maintaining breathability to prevent trapped moisture accumulation beneath the flooring surface. These treatments extend beyond basic water resistance to include protection against common household chemicals, cleaning agents, and organic stains that could otherwise compromise both appearance and structural integrity. The molecular structure of these protective coatings ensures long-term performance without degradation under ultraviolet light exposure or repeated cleaning cycles.

Performance Standards and Durability Metrics

Wear Resistance Classifications

Understanding wear resistance classifications helps consumers select waterproof vinyl flooring appropriate for their specific usage requirements and traffic patterns. Commercial-grade waterproof vinyl flooring typically features wear layers measuring 20 mils or thicker, providing exceptional resistance to abrasion, scratching, and impact damage in high-traffic environments. Residential applications often perform adequately with wear layers ranging from 12 to 20 mils, depending on household activity levels and long-term durability expectations.

Industry testing standards evaluate waterproof vinyl flooring performance through standardized protocols that measure resistance to chair caster movement, heel impact, and furniture leg indentation. These comprehensive testing procedures simulate decades of normal use within accelerated timeframes, providing reliable predictors of real-world performance. Quality manufacturers provide detailed performance data that enables direct comparison between different waterproof vinyl flooring options, helping consumers align product specifications with their specific requirements and budget constraints.

Temperature and Humidity Stability

Superior waterproof vinyl flooring maintains dimensional stability across extreme temperature and humidity variations without experiencing expansion, contraction, or warping that could compromise installation integrity. This stability proves particularly important in geographic regions with significant seasonal climate variations or in buildings with fluctuating environmental control systems. The coefficient of thermal expansion for quality waterproof vinyl flooring remains minimal, ensuring consistent performance in applications ranging from heated bathroom floors to climate-controlled commercial spaces.

Humidity resistance extends beyond surface waterproofing to encompass the flooring's ability to function properly in environments with elevated moisture levels, such as coastal regions or humid subtropical climates. Premium waterproof vinyl flooring incorporates moisture-resistant core materials that prevent swelling, delamination, or dimensional changes when exposed to atmospheric humidity levels that might damage traditional flooring materials. This comprehensive environmental resistance makes waterproof vinyl flooring suitable for applications where other flooring types would fail or require extensive maintenance.

Installation Considerations and System Compatibility

Subfloor Preparation Requirements

Proper subfloor preparation forms the foundation for successful waterproof vinyl flooring installation, directly impacting long-term performance and warranty coverage. Quality waterproof vinyl flooring systems accommodate minor subfloor imperfections while still requiring adequate surface preparation to ensure optimal results. Subfloor moisture levels must remain below specific thresholds, typically requiring testing with calibrated moisture meters to verify compliance with manufacturer specifications before installation begins.

The compatibility between waterproof vinyl flooring and various subfloor types influences installation methods and long-term performance outcomes. Concrete subfloors require moisture vapor barrier consideration, while wooden subfloors may need additional structural reinforcement to prevent deflection that could stress locking mechanisms or create gaps between planks. Understanding these compatibility requirements helps property owners budget appropriately for preparation work and ensures optimal performance from their waterproof vinyl flooring investment.

Installation Method Flexibility

Modern waterproof vinyl flooring systems offer multiple installation methods that accommodate different skill levels, project timelines, and budget constraints. Floating installation methods utilize advanced locking mechanisms that create stable, unified floor surfaces without requiring adhesive attachment to subfloors. This approach simplifies installation while maintaining the ability to remove or replace individual sections if damage occurs, providing long-term maintenance advantages that reduce total ownership costs.

Alternative installation methods include full-spread adhesive applications that create permanent bonds between waterproof vinyl flooring and subfloor surfaces, providing maximum stability in high-traffic commercial applications. Hybrid installation techniques combine floating and adhesive methods to optimize performance characteristics while maintaining installation flexibility. The choice between these methods depends on specific application requirements, environmental conditions, and long-term maintenance expectations that vary across different property types and usage patterns.

Aesthetic Options and Design Flexibility

Surface Texture and Visual Authenticity

Contemporary waterproof vinyl flooring achieves remarkable visual authenticity through advanced printing technologies and surface texturing techniques that replicate natural materials with exceptional accuracy. Embossed-in-register technology synchronizes visual wood grain patterns with corresponding surface textures, creating tactile experiences that closely mirror genuine hardwood flooring. These sophisticated manufacturing processes enable waterproof vinyl flooring to provide the aesthetic appeal of premium natural materials while delivering superior moisture resistance and maintenance convenience.

The variety of available surface textures extends beyond traditional wood appearances to encompass stone, ceramic tile, and contemporary abstract patterns that complement diverse interior design preferences. Micro-beveled edges enhance plank definition while creating shadow lines that add dimensional depth to floor installations. These design elements contribute to the overall visual impact of waterproof vinyl flooring while maintaining the practical benefits that make this flooring type suitable for challenging moisture-prone environments.

Color Consistency and Fade Resistance

Quality waterproof vinyl flooring maintains color consistency across manufacturing batches while providing long-term fade resistance that preserves aesthetic appeal throughout the product's service life. Advanced colorant technologies prevent ultraviolet light degradation that could cause color shifts or fading in areas exposed to direct sunlight. This stability ensures that waterproof vinyl flooring maintains its intended appearance regardless of installation location or exposure conditions.

The printing process for premium waterproof vinyl flooring incorporates high-definition imagery that creates realistic variation patterns mimicking natural material characteristics. This technology eliminates the repetitive appearance that characterized earlier vinyl flooring generations, enabling large installations that maintain visual interest without obvious pattern repetition. Color matching capabilities allow for seamless integration with existing design elements while providing flexibility for future remodeling or expansion projects.

Maintenance Requirements and Long-term Care

Daily Cleaning and Maintenance Protocols

The maintenance requirements for waterproof vinyl flooring contribute significantly to its total cost of ownership and practical appeal for busy households and commercial facilities. Daily maintenance typically involves simple dry sweeping or vacuuming to remove surface debris, followed by damp mopping with pH-neutral cleaning solutions that preserve surface treatments without leaving residue buildup. The non-porous surface of quality waterproof vinyl flooring prevents dirt and stain penetration, simplifying cleaning procedures while reducing the need for specialized cleaning products or equipment.

Routine maintenance schedules for waterproof vinyl flooring focus on preserving the protective wear layer while addressing normal wear patterns that develop over time. Preventive maintenance measures include furniture pad installation, entrance mat systems, and periodic deep cleaning that removes accumulated soil without damaging surface treatments. These straightforward maintenance requirements make waterproof vinyl flooring particularly attractive for applications where cleaning efficiency and time management are important considerations.

Repair and Replacement Considerations

The repair capabilities of waterproof vinyl flooring systems influence long-term ownership costs and practical convenience for property managers and homeowners. Individual plank or tile replacement remains possible with floating installation systems, enabling targeted repairs that address localized damage without disturbing surrounding flooring areas. This replaceability feature provides significant advantages over monolithic flooring systems that require extensive demolition and replacement when damage occurs.

Professional repair services for waterproof vinyl flooring typically involve surface refinishing techniques that restore appearance and performance characteristics without requiring complete replacement. Understanding these repair options helps property owners budget appropriately for long-term maintenance while maximizing the service life of their flooring investment. The availability of matching replacement materials depends on manufacturer inventory policies and product lifecycle management, making it important to consider these factors during initial product selection.

FAQ

How does waterproof vinyl flooring perform in high-moisture environments like bathrooms

Waterproof vinyl flooring excels in high-moisture environments due to its impermeable core construction and sealed edge technology that prevents water infiltration. The multilayer system resists warping, buckling, and delamination even when exposed to standing water or high humidity levels. Professional-grade waterproof vinyl flooring installations include moisture barriers and proper drainage considerations that ensure long-term performance in shower areas, laundry rooms, and commercial kitchens where moisture exposure is constant.

What thickness should I choose for my waterproof vinyl flooring application

Thickness selection for waterproof vinyl flooring depends on traffic levels, subfloor conditions, and performance expectations. Residential applications typically perform well with overall thicknesses ranging from 4mm to 8mm, while commercial installations often require 8mm to 12mm thickness for optimal durability. The wear layer thickness, measured separately from overall product thickness, should be at least 12 mils for residential use and 20 mils or greater for commercial applications to ensure adequate abrasion resistance.

Can waterproof vinyl flooring be installed over existing flooring materials

Waterproof vinyl flooring can often be installed over existing flooring materials, provided the substrate meets manufacturer specifications for flatness, stability, and moisture content. Existing ceramic tile, hardwood, and laminate flooring may serve as suitable substrates when properly prepared and evaluated. However, carpet and cushioned vinyl require removal to ensure proper adhesion and prevent future problems. Professional evaluation helps determine substrate suitability and preparation requirements for successful installation.

How long does quality waterproof vinyl flooring typically last in residential applications

Quality waterproof vinyl flooring in residential applications typically provides 15 to 25 years of service life when properly installed and maintained. Factors affecting longevity include wear layer thickness, traffic patterns, maintenance quality, and environmental conditions. Premium products with thicker wear layers and superior construction often exceed manufacturer warranty periods, while proper maintenance practices significantly extend service life regardless of initial product quality. Regular professional evaluation helps identify maintenance needs that preserve performance and appearance over time.

Table of Contents

- Core Construction Features of Quality Waterproof Vinyl Flooring

- Performance Standards and Durability Metrics

- Installation Considerations and System Compatibility

- Aesthetic Options and Design Flexibility

- Maintenance Requirements and Long-term Care

-

FAQ

- How does waterproof vinyl flooring perform in high-moisture environments like bathrooms

- What thickness should I choose for my waterproof vinyl flooring application

- Can waterproof vinyl flooring be installed over existing flooring materials

- How long does quality waterproof vinyl flooring typically last in residential applications